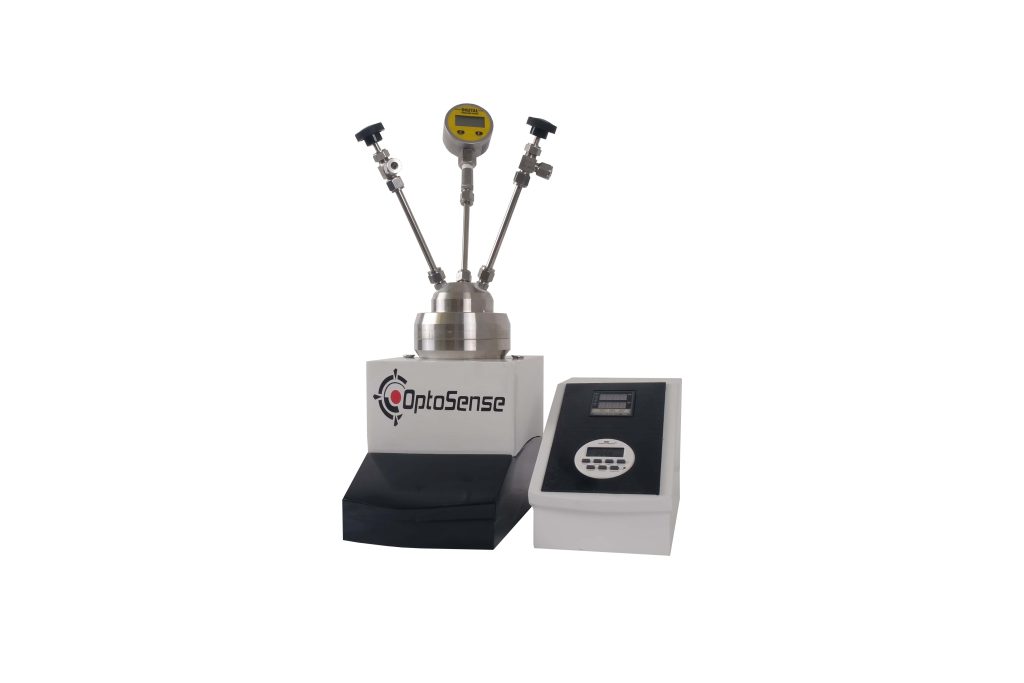

Reactor System

Optosense The high pressure reactor system produce all materials from the solutions such organic materials and metal oxides and all-in solutions for various applications. System produce materials from the solution as POWDER AND THIN FILMS on any substrate.

SALE PRICE: RFQ

A reactor system can refer to various systems or devices, depending on the context in which it is used. Generally, a reactor system is a setup designed to facilitate and control chemical, physical, or nuclear reactions.

Working principle of Reactor System

The working principle of a reactor system depends on its type and purpose. I’ll provide a general overview of the working principles of chemical reactors, nuclear reactors, and bioreactors, which are among the most common types of reactor systems:

Chemical Reactor System:

–Mixing: Chemical reactants are introduced into the reactor and mixed to ensure a uniform distribution of substances.

–Reaction Control: The reactants are subjected to specific temperature, pressure, and other conditions to initiate and control the desired chemical reaction. This can be achieved through heating or cooling systems, pressure vessels, and the addition of catalysts or initiators.

Residence Time: The reactants are allowed to stay within the reactor for a specified residence time to complete the reaction. The design of the reactor may be batch, continuous flow, or other configurations based on the specific process requirements.

Nuclear Reactor System:

–Nuclear Chain Reaction: Nuclear reactors rely on nuclear fission (splitting of atomic nuclei) or nuclear fusion (combining atomic nuclei) to release energy. Control rods and moderators are used to control the rate of the nuclear chain reaction.

–Heat Generation: The energy released from nuclear reactions is converted into heat, which is used to produce steam in most nuclear power plants.

–Cooling and Heat Transfer: The heat produced needs to be managed by cooling systems, typically involving water or coolant, to prevent overheating. The transferred heat is used to generate steam, which drives turbines to produce electricity.

Bioreactor System:

–Microorganism or Cell Cultivation: Bioreactors are used to grow microorganisms, cells, or tissues for various biotechnological or pharmaceutical applications. Nutrient-rich media are introduced to support growth.

–Control of Environmental Factors: Environmental conditions such as temperature, pH, oxygen levels, and agitation are closely controlled to optimize cell growth and productivity.

–Monitoring and Sampling: Sensors are used to monitor the growth process, and samples may be periodically withdrawn for analysis.

The key working principles of reactor systems involve maintaining the desired conditions for the intended reactions, be they chemical, nuclear, or biological. Additionally, safety features and control mechanisms are implemented to prevent accidents and ensure the stability and efficiency of the system. The specific design and operation of a reactor system will depend on its intended application and the type of reaction it facilitates.system

What are the usage areas of reactor system?

Systems are used in various fields and industries to facilitate and control a wide range of chemical, physical, or nuclear processes. Here are some of the usage areas of reactor systems:

Chemical Industry:

–Chemical Synthesis: Systems are used for the production of chemicals, pharmaceuticals, and specialty materials by facilitating chemical reactions.

–Polymerization: Polymerization reactors are employed to create polymers and plastics.

–Refining: Refineries use catalytic reactors to process crude oil into fuels and other products.

Energy Generation:

–Nuclear Power: Nuclear reactor systems are used to generate electricity by harnessing the energy released through nuclear fission or fusion.

–Thermal Power: Combustion or steam generators can be considered reactor systems in the context of thermal power generation.

Biotechnology and Pharmaceutical Industry:

–Bioprocessing: Bioreactor systems are utilized for the cultivation of microorganisms, cells, or tissues to produce bioproducts, including vaccines, therapeutic proteins, and enzymes.

–Fermentation: Fermentation reactors are employed for the production of various bioproducts such as ethanol, organic acids, and antibiotics.

Research and Development:

–Scientific Experiments: Research reactors are used for scientific research in nuclear physics, materials science, and other fields.

–Laboratory and Pilot-Scale Testing: Reactor systems are commonly used in laboratories and pilot plants to develop and test new processes and products.

Environmental Control:

–Waste Treatment: Reactor systems are used in wastewater treatment plants to facilitate biological and chemical processes for removing pollutants.

–Air Pollution Control: Certain reactor systems are employed to control air emissions by converting pollutants into less harmful substances.

Metallurgy and Material Science:

–Metallurgical Processes: Reactor systems are used in the production of metals and alloys through smelting and refining processes.

–Materials Synthesis: Reactors are used for the synthesis of advanced materials, composites, and nanomaterials.

Space and Propulsion:

–Spacecraft Propulsion: Nuclear reactors have been considered for powering spacecraft for deep space exploration.

–Nuclear Propulsion: In certain applications, nuclear reactors have been explored for marine propulsion in submarines.

Petrochemical Industry:

–Cracking and Reforming: Systems play a role in the cracking of hydrocarbons to produce valuable products like gasoline and the reforming of compounds to enhance their quality.

Food and Beverage Production:

–Fermentation: Systems are used in the production of alcoholic beverages, dairy products, and various food additives through fermentation processes.

Research and Education:

–Universities and Research Institutions: Systems are used for educational and research purposes in fields like chemistry, engineering, and nuclear physics.

The usage areas of systems are diverse and depend on the specific processes they are designed for. These systems play a crucial role in various industries by enabling controlled reactions, energy generation, and the production of valuable products and materials.